GHFM-02

A portable Guarded Heat Flow Meter for the Thermal Conductivity Measurement of Metals, Polymers and Composites. GHFM-02 follows the trusted steady-state approach, with the addition of a guard to limit the effects of lateral heat loss.

ASTM E1530-19

FEATURED GUARDED HEAT FLOW METER CAPABILITIES

The Guarded Heat Flow Meter (GHFM-02) follows ASTM E1530-19 for testing thermal resistance and thermal conductivity of solids, such as metals, polymers and composites. The easy to operate GHFM-02 follows the trusted steady-state approach, with the addition of a guard to limit the effects of lateral heat loss. This design, allows testing of a wide range of materials with low to medium thermal conductivity.

According to the method, the sample is subjected to a steady-state through-thickness temperature gradient. The thermal conductivity of the sample is obtained by measuring the temperature difference across it, and one additional temperature.

The testing stack is made up of a heater – upper plate, with integrated temperature sensor and heat sink – lower plate with integrated temperature sensor on each side of the sample. Additional temperature sensors are placed near the top and bottom surface of the sample.

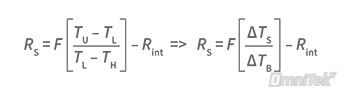

Once steady-state temperature across sample is achieved, the Fourier law equation can be applied. It can readily be shown that for any solid sample, the ratio RS (m2 K/W), equal to the thickness of the sample, d (m), to its thermal conductivity, λ (W/mK), can be obtained from the temperatures measured:

The above equation is linear in form, and is the working equation of the instrument. Constants F (m2 K/W) and Rint (m2 K/W), can be obtained by calibration of the instrument. To this effect, calibration samples of known thermal conductivity and hence, thermal resistance, are employed. Calibrated results for thermal resistance and thermal conductivity are reported.

- Follows international standard ASTM E1530-19

- Economical and Accurate

- Easy to use

- Variable Thickness

GHFM-02 SPECIFICATIONS

| Materials | Metals, Polymers and Composites |

| Measurement Capabilities | Through-Thickness |

| Thermal Resistance | 0.00007 to 0.25 m2 K/W |

| Thermal Conductivity | 0.1 to 15 W/mK |

| Measurement Time | Typically 30-60 minutes |

| Reproducibility | 2% |

| Accuracy | 5% |

| Temperature | 20°C – 30°C |

| Sample Diameter | 50.8 mm / 2 in. |

| Maximum Thickness | 25.4 mm / 1 in. |

| Standards | ASTM E1530-19 |

ECONOMICAL. ACCURATE.

STANDARD GHFM-02 TESTING STACK

The GHFM-02 comes with a standard 50.8 mm (2 inches) diameter sample opening to allow testing of metals, polymers and composite materials. Sample thickness can vary up to 25.4 mm (1 inch). Typically a 20°C temperature delta from top to bottom of the sample is set to a mean temperature of 20°C to 30°C. Temperature points TU , TL and TH are then entered into the included GHFM software for auto calculation of thermal resistance and calibrated thermal conductivity results.

CALIBRATION

The basic GHFM-02 comes calibrated to calculate thermal conductivity from thermal resistance range of 0.0032 to 0.1270 m2 K/W. Additional available calibration ranges allow testing from 0.00007 to 0.25 m2 K/W.

SAMPLE MEASUREMENT

1

THE SAMPLE

GHFM-02 samples should be 50.8 mm or 2 inches in diameter. The top and bottom surfaces should be flat and parallel.

Approximate Time: < 1 minute

2

PLACE SAMPLE ON GHFM-02 TESTING STACK

A thin layer of the included contact paste should be added to the top and bottom of the sample surface.

Approximate Time: < 2 minutes

3

MEASUREMENT

For a sample mean temperature of 25°C, the top heater should be set to 35°C, while the bottom heat sink chiller – circulator set to 15°C to achieve a delta temperature of 20°C.

Approximate Time: < 2 minutes

4