DIL 402 Expedis Select & Supreme

Dilatometry Redefined.

The new dilatometer DIL 402 Expedis Select and Supreme offer state-of-the-art dilatometer technology and are designed for a wide range of sophisticated applications. All instruments of the DIL Expedis series feature the revolutionary NanoEye measuring cell; a new dimension in measuring range and accuracy.

It is the first horizontal dilatometer series on the market which allows for force modulation and, by this means, bridges the gap between dilatometry and thermomechanical analysis (TMA) under oscillatory load.

These two versions are specially designed for both research & development and sophisticated industrial applications: The comprehensive, fully-equipped Supreme model and the upgradable Select type.

A New Dimension in Measuring Range and Accuracy

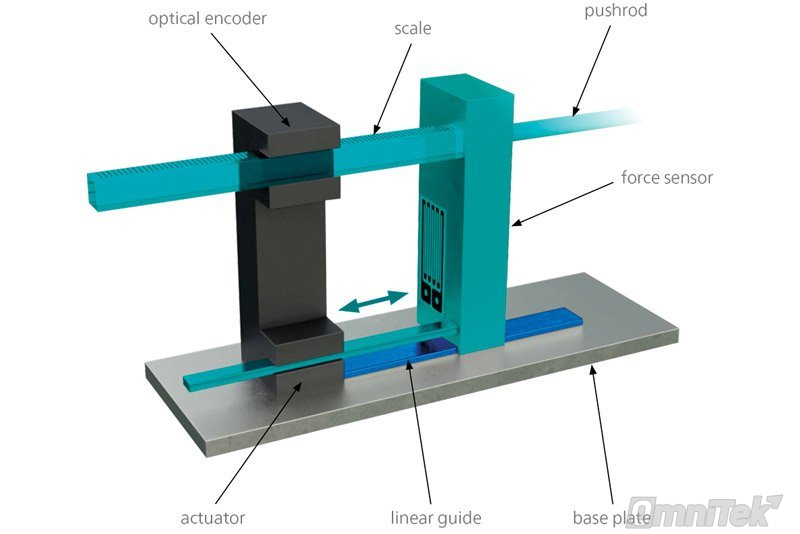

In classical dilatometry, the two parameters measurement range and resolution mostly seem diametrically opposed. If the resolution goes up, the measuring range usually goes down and vice versa. NanoEye, the novel opto-electrical displacement system, features perfect linearity and maximum resolution over a measuring range which was impossible to realize until now.

Automatic Sample Length Detection & MultiTouch

Measuring the sample length with a caliper runs the risk of result scatter, especially for soft samples. The DIL 402 Expedis is capable of detecting the initial length of a sample automatically prior to the start of a test run under condi-tions identical to those during the measurement itself.

A stable position of the sample inside the sample holder is a deciding factor for successful measurement results. The MultiTouch feature places the sample into the optimum position using a unique, tail-like motion.

In order to conveniently measure various sample lengths, the thermocouple is adjustable. A guiding rod accommodates the thermocouple for moving it into the desired position without bending.

High Temperature Version

Up to 2800°C

Variable Gas Atmosphere Is Key

In the DIL 402 Expedis Supreme HT instrument, the sample chamber and furnace chamber are always separated by means of a protective tube (glassy carbon or alumina). This allows for the use of a different atmosphere around the sample than around the heating elements.In combination with an alumina protective tube (maximum furnace temperature: 1680°C), even an air atmosphere can be applied to the sample.

The optional AutoVac system for evacuating and refilling the sample chamber along with integrated purging of the pyrometer window effectively supports the direct switch between oxidizing and inert conditions.

Broadest Application Range

Two graphite furnaces with end temperatures of 2400°C and 2800°C provide the appropriate configuration for measuring the thermal expansion of metals, alloys, ceramics and composites in applications such as aerospace, power generation, the oil and gas industry or demanding research.

However, via an adapter, each of these graphite furnaces can be replaced with a standard furnace such as SiC, SiO2, Cu or steel. The opposite is also feasible: A DIL 402 Expedis Supreme HT measuring part with a standard furnace can be subsequently retrofitted with a high-temperature furnace.