Thermoreflectance by Pulsed Light Heating

NanoTR/PicoTR

Thermoreflectance – The Laser Flash Method for Thin Films

In modern industries, the knowledge of thermal properties, specifically thermophysical properties, becomes more and more important. They are required, for example, for the development of heat release materials of advanced and miniaturized electronics, thermoelectric materials as sustainable energy, insulating materials for saving energy, TBCs (thermal barrier coatings) for turbine blades, and safety operation of nuclear plants, etc.

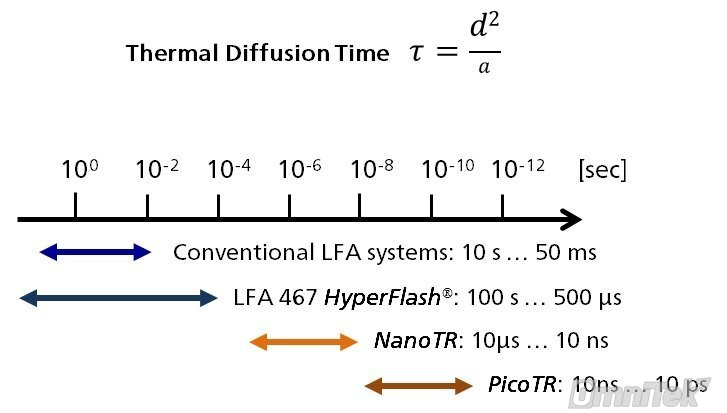

Among the thermophysical properties, the thermal conductivity is of paramount importance. The determination of the thermal diffusivity/thermal conductivity can be realized with the established laser flash method (LFA). This method has been known for many years to provide reliable and accurate results. Sample thicknesses typically range from 50 μm to 10 mm.

NETZSCH is a world-wide leading manufacturer of instruments for testing thermophysical properties, specifically of laser flash analyzers. These LFA systems are used in the fields of ceramics, metals, polymers, nuclear research, etc.

With the significant progress in the design of electronic devices and the associated need for an efficient thermal management, accurate thermal diffusivity / thermal conductivity measurements in the nanometer range are more than ever crucial.

The National Institute of Advanced Industrial Science and Technology (AIST), Japan, already responded to industrial requirements with the development of a “pulsed light heating thermoreflectance method” in the early 90’s. PicoTherm Corporation was established in 2008 with the launch of a nano-second thermoreflectance apparatus “NanoTR” and a pico-second thermoreflectance apparatus “PicoTR”, which allows for absolute measurements of the thermal diffusivity of thin films in a thickness range of several 10 μm down into the nanometer range.

In 2014, NETZSCH Japan K.K, a subsidiary of NETZSCH, became the exclusive representative of the PicoTherm Corporation. In combination with our LFA systems, NETZSCH can now offer the solution for thin films in the nanometer range up to bulk materials in the range of mm.

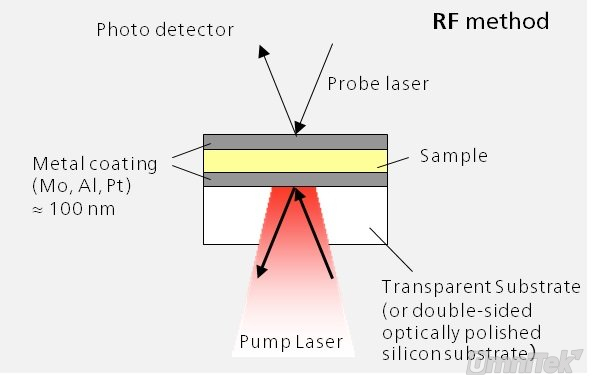

The fact that the thermophysical properties of thin layers and films differ considerably from those of the corresponding bulk material requires a technique which overcomes the limitations of the classical laser flash method (LFA). This so-called ultrafast laser flash technique is also known as the rear heating/front detection method.

The measurement setup is similar to the conventional LFA: detector and laser are on opposite sides of the sample which is located on a transparent substrate. The measured thermal diffusivity is the component through the thickness perpendicular to the sample’s surface. The pump laser irradiates the sample’s rear side.

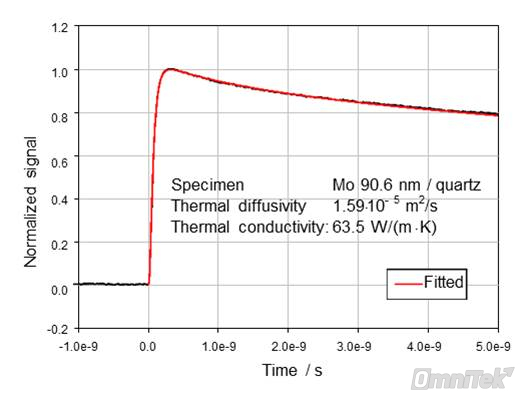

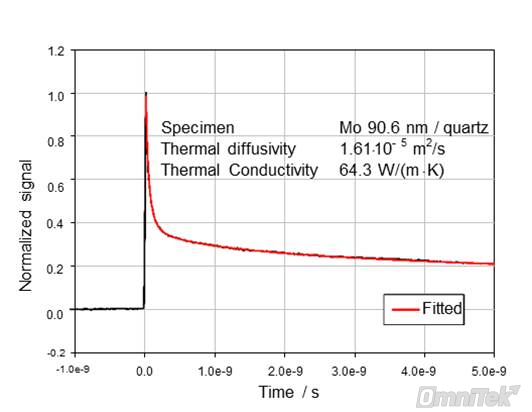

As the sample heats up, its surface thermoreflectance varies. The thermal diffusivity is calculated from the temperature rise (lower plot). Here, the thermal diffusivity of a thin metal film (Mo) was determined to 1.59 • 10-5 m2/s.

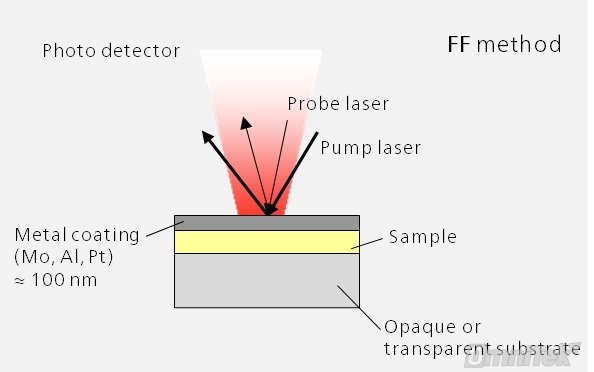

In addition to the RF method, measurements can also be made in a front heating/front detection (FF) configuration. The term “front” refers to the open surface of the thin film deposited on a substrate, while “rear” refers to the boundary between the thin film and the substrate.

In the FF measurement setup (upper picture), the detector and laser are on the same side of the sample. An area of the front face of the thin film with a diameter of several tens of micrometers is heated by a pump laser, and a probe laser points at the same position. The change in the surface temperature is observed.

This method can be applied to thin layers on non-transparent substrates for which the RF technique is not suitable.

In the example on the left, the thermal diffusivity of a thin metal film (Mo) was determined to 1.61 • 10-5 m2/s by applying the FF method. The results prove the high agreement between RF and FF modes (deviation < 2%).

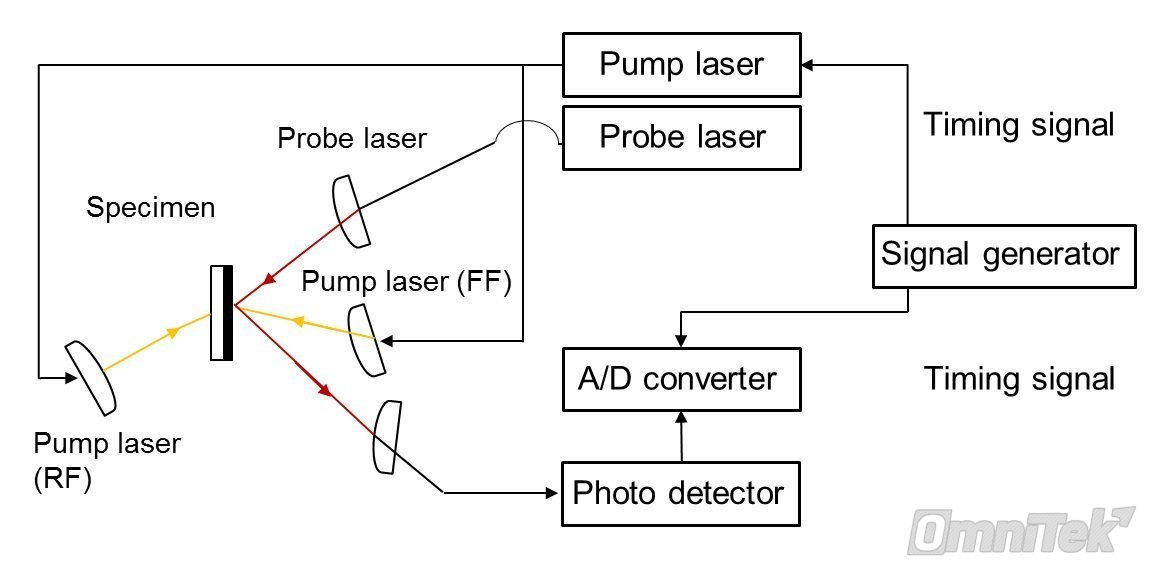

NanoTR’s state-of-the-art signal processing technology allows high speed measurements. With this thermoreflectance apparatus, a laser pulse of 1 ns pulse width is periodically (20 μs) irradiated to the sample. The resulting temperature response is applied to a CW laser (probe laser). Excellent s/n ratio can be attained by high speed integration of repetitive signals. It can be easily switched between the RF and FF configurations though the software for a wide variety of samples.

NanoTR is in accordance with JIS R 1689, JIS R 1690, and SI traceable by the thin film standard of heat diffusion time (RM1301-a), supplied from AIST.